Schiedel FLUE LINERS SIH

High performance rebated ceramic flue liners and accessories

In order to meet the new European Standards for Chimney products, Schiedel has sourced the finest raw materials, blended in a unique formula to give a unique combination of temperature resistance and strength.

A cost effective way of building a chimney in a home, therefore reducing the need for gas and electric, due to high charges, as well as being a superb focal point and a heating source during any power cuts.

Schiedel have invested in the latest production technology and are proud to introduce a full range of high performance rebated ceramic flue liners and accessories, which are fully CE tested and CPR approved.

- Suitable for all fuels – gas, oil, solid fuels and biomass fuels.

- Wide range of accessories to suit numerous installations.

- Suitable for high temperature and low temperature applications.

- Full compliance to the latest CE standards and Construction Products Regulations (CPR).

- Continuous straight flue liners ensure a consistency in backfill insulation.

- Cleaning and Inspection liners as standard products.

| Designation Code: High Temperature | EN 1457-1 A1 N1 T600 G |

| Designation Code: Low Temperature | EN 1457-2 B4 N1 T400 WC 0 EN 1457-2 D4 N1 T200 WC 0 |

| Fuel | Oil, Gas, Solid Fuels, Biomass Fuels |

| Exhaust Temperature | 600⁰C |

| Inner Liner | High Grade Ceramic |

| Test Pressure | Test Pressure 40 Pa (2m3. s-1. m-2 x 10-3) |

| Thermal Resistance | 0.00463 m2K/W |

The construction and application of chimneys and flues is covered by Building Regulations in conjunction with the relevant European Standards. Whilst these differ in emphasis, they all mandate the safe application of the chimney no matter where and how used. These Regulations and Standards dictate the minimum criteria which it is necessary to apply if the chimney or flue is to function safely and correctly.

Building control approval is necessary for building new chimneys and in some cases for relining old chimneys particularly if some alteration or change of the heating appliance occurs. The appropriate Regulations and Standards are listed below.

England & Wales:

Building Regulations Approved Document J

Scotland:

Building Regulations Technical Standards

Northern Ireland:

Building Regulations Technical Booklet L

Republic of Ireland:

Building Regulations Technical Guidance Document J

It is important to match the internal diameter of the flue with the outlet on the appliance. It should never be less than the outlet diameter of the appliance. The appliance manufacturer’s chimney sizing recommendations should always be followed.

For open fires with a standard fire opening up to 500mm wide by 550mm high the minimum required flue diameter is 200mm round. For larger open fires, such as inglenooks, dog grate installations or special appliances and stoves designed to operate with a fire opening greater than 500mm x 550mm, the flue size should be at least 15% of the free unobstructed area of the fire opening (including sides if open). Many Decorative Fuel Effect gas fires (DFE’s) that imitate a coal or log burning open fire require the same chimney arrangement as for solid fuel open fires and must be installed in accordance with respective local building regulations

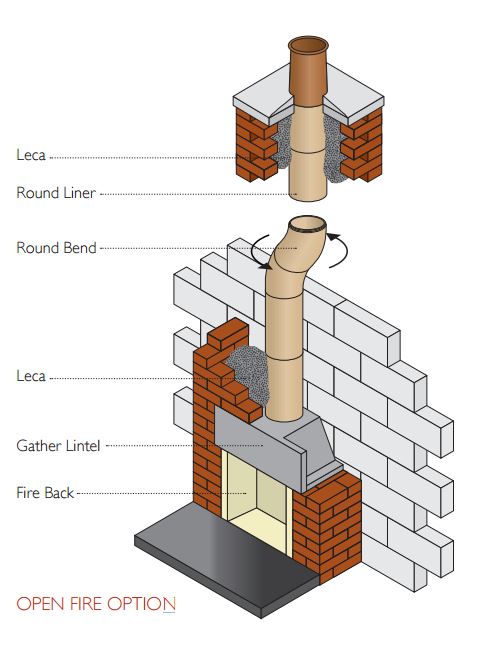

Construction begins by providing a suitable foundation and constructional hearth in accordance with local Building Regulations and site requirements.

Form the fire opening onto the constructional hearth. 100mm of brick or blockwork must be built around the sides and back of the firechest to comply with Building Regulations.

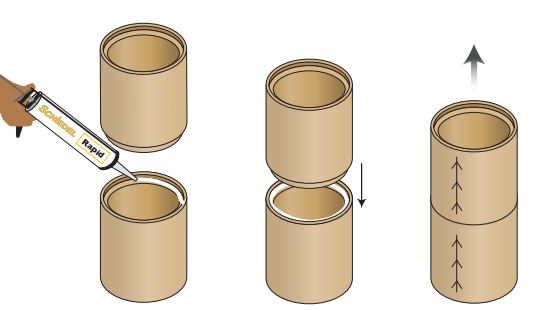

Apply Schiedel Rapid HT Cement onto a suitably formed fire gather. Position the flue liner onto the prefabricated gather, female rebate facing upwards. Arrows on each flue liner indicate the directional flow of flue gases. Continue to apply Schiedel Rapid HT Cement to each flue liner, cleaning any access material from the joints.

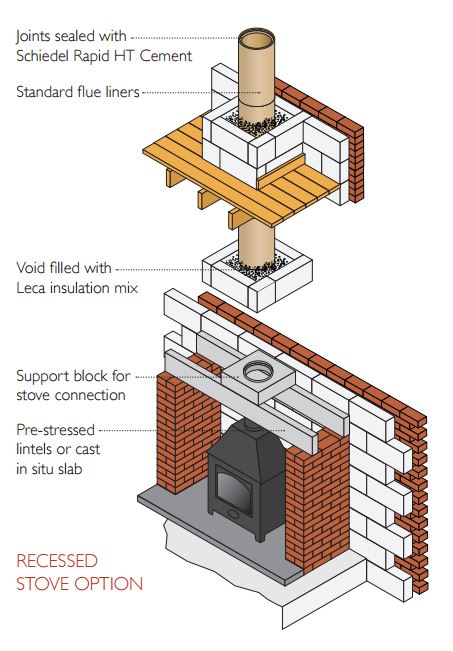

A suitable cast-in-situ concrete slab lintel must be provided above the fireplace recess. Alternatively you could use suitable pre stressed lintels, for this method a support plate is required under the support block. It is recommended to have a minimum of 600mm length of flue pipe before connecting to the chimney.

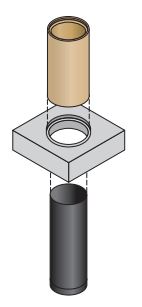

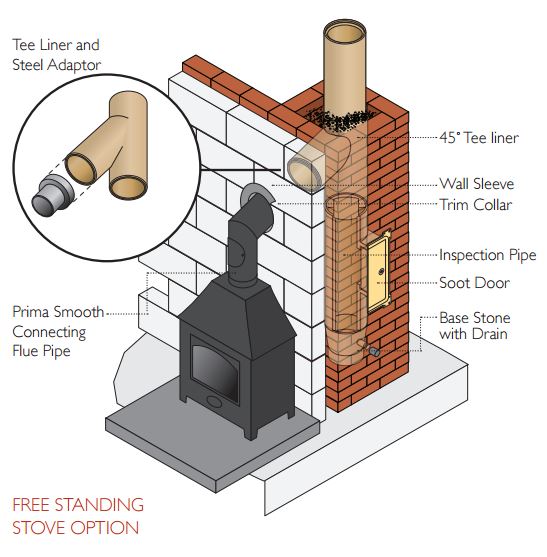

The support block is bedded onto the slab lintel using weak mix mortar. A stainless steel adaptor or a section of Prima Smooth connecting flue pipe is used to connect from the support block to the stove flue pipe. This adaptor is pushed up onto the support block spigot (fibre rope should be used to create a seal).

Apply Schiedel Rapid HT Cement onto a suitably formed fire gather. Position the flue liner onto the prefabricated gather, female rebate facing upwards. Arrows on each flue

liner indicate the directional flow of flue gases. Continue to apply Schiedel Rapid HT Cement to each flue liner, cleaning any access material from the joints. The support block is bedded onto the slab lintel using weak mix mortar. A stainless steel adaptor or a section of Prima Smooth connecting flue pipe is used to connect from the support block to the stove flue pipe. This adaptor is pushed up onto the support block spigot (fibre rope should be used to create a seal).

A soot door must be provided below the flue pipe entry to allow for inspection and removal of soot and debris. A suitable wall sleeve is to be used to seal the cavity wall. Any combustible insulation within the wall must be kept away from the single skin connecting flue pipe by at least 1.5 x its diameter. (Example: diameter 150mm x 1.5 = 225mm distance).

The flue pipe is a push fit over the spigot on the adaptor. Seal off the gap between the flue pipe and wall sleeve with fire proof rope and closing plate.

Apply Schiedel HT Cement onto the male rebate of the flue liner.

Position the flue liner on a suitably formed fire gather or support block with the female rebate facing upwards. Arrows on each flue liner indicate the directional flow of flue gases. Continue to apply high temperature cement to each flue liner, cleaning any access material from the joints.

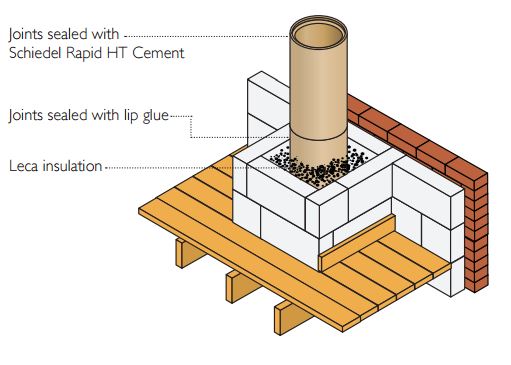

Clad the flue liners with a minimum of 100mm suitable masonry. A minimum of 15mm Leca insulation must be installed between the flue liners and masonry. Mix 20 parts Leca to 1 Part cement and a small amount of water. Ensure it is well mixed before using.