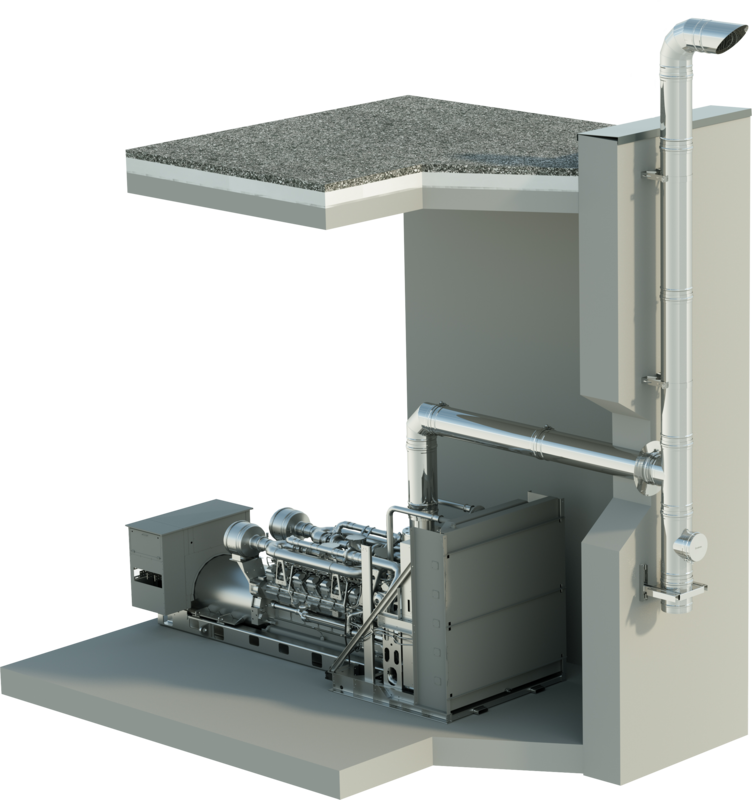

ICS 5000 is a multi-functional twin wall insulated venting system, which is suitable for internal and external use on a wide range of engineering, combustion and process equipment, including heating appliances, diesel generators, CHP systems and service ducting.

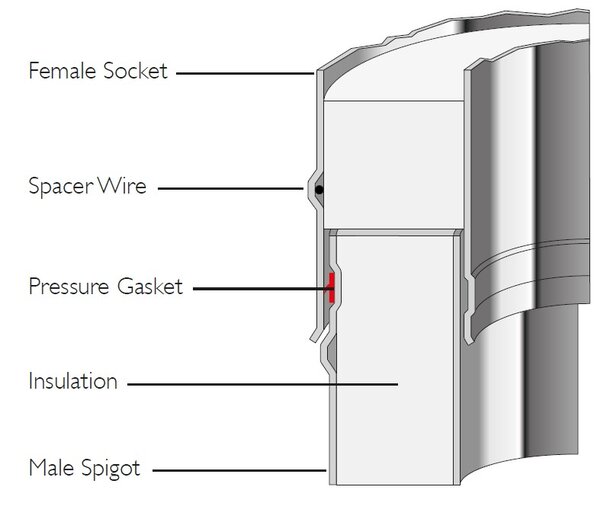

ICS 5000 comes with a high quality specification as standard with a 316L Grade Stainless steel liner, high performance mineral blanket insulation and a bright annealed 304 Grade stainless steel outer case.

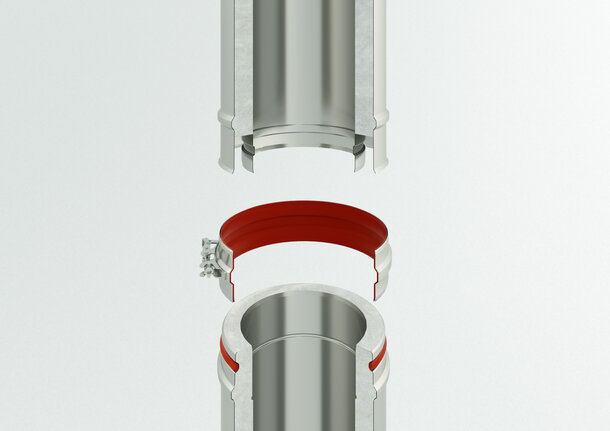

Both liner and outer case have a continuous seam welded joint and each flue gas bearing component has a uniquely profiled spigot and socket joint with bevelled end forms to ensure ease of installation whilst ensuring the joint meets H1 performance criteria at 5000 Pa.

The thermal insulation blanket ensures continuous insulation over the entire effective length of the liner, ensuring fast priming to normal operating temperatures, whilst maintaining low external surface temperatures.

Heating appliances

Stand-by gensets

Combined heat and power (CHP)

Service ducting.

ICS 5000 is tested and approved in both 25mm and 50mm variants to BS EN 1856-1 as a System Chimney and to BS EN 1856-2 as a connecting flue pipe with the following designations

System Chimney BS EN 1856-1 (TÜV 0036 CPR 9195 027)

T600 H1 D V3 L50050 O75*

T200 H1 W V2 L50050 O50**

Distance to combustibles

*Ø80-Ø300 distance - 75mm

*Ø350-Ø450 distance - 112.5mm

*Ø500- Ø600 distance - 150mm

**Ø80-Ø200 distance - 50mm

Connecting Flue Pipe BS EN 1856-2 (TÜV 0036 CPR 9195 038)

ICS 5000 UK version 18-01-23.pdfICS 5000 UK version 18-01-23.pdf T600 H1 D V3 L50050 O100 M

System Chimney BS EN 1856-1 (TÜV 0036 CPR 9195 027)

T600 H1 D V3 L50050 O25

Distance to Combustibles

Ø80-Ø300 distance - 25mm

Ø350-Ø450 distance - 37.5mm

Ø500- Ø600 distance - 50mm

BS EN 1856-2 (TÜV 0036 CPR 9195 038)

T600 H1 D V3 L50050 O100 M

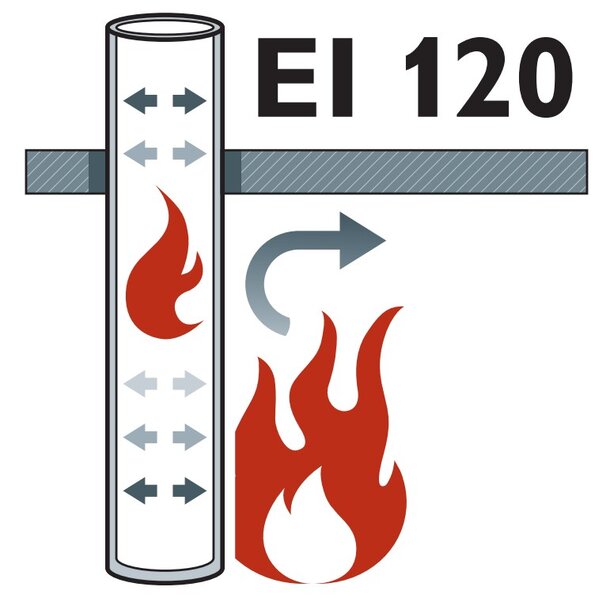

EI 120 Fire rating to BS EN 1366-13 Chimneys

ICS25 5000

ICS50 5000

Horiziontal and Vertical

BS 476 part 20 (4 Hour Fire Rating)

ICS25 5000

ICS50 5000

Corrosion testing on Gas, Oil, Solid Fuel (TÜV 0036 CPR 9195 027)

Gastec, MPA,TÜV

A typical installation showing a boiler system with noise reduction features.

A typical installation showing a boiler system with noise reduction features in a horizontal installation.

Chimneys are subject to significant corrosion attack by flue gas condensates, particularly from solid fuel and condensing appliances. ICS is specifically designed and manufactured to resist this corrosion. It is the only stainless steel chimney system in the world to have passed the internationally recognised Gastec corrosion test.

The chimney size should be as recommended by the appliance manufacturer. Where there is a requirement for a flue diameter smaller than the appliance spigot, then the operational requirements of the appliance and the configuration of the flue must satisfy the flue sizing requirements of BS EN 13384-1 for single appliances.

Schiedel has recently successfully carried out fire resistance tests according to the latest European standard EN 1366-13:2019 “Fire resistance tests for service installations, Part 13: Chimneys” and has reached EI 120 classification for our Double Wall Insulated System Chimney ICS in a closed scenario (type A) for both vertical and horizontal set-ups.

Schiedel is the first European chimney manufacturer to have performed the tests according to this latest fire resistance standard for chimneys.

Helpful sections for chimney installers

| Basic data (dimensions, weight & co.) | |

Wall thickness per diameter (internal) |

0,5 - 1,0 mm |

Wall thickness per diameter (outside) |

0,5 - 0,7 mm |

| Application | |

Flue gas temperature (dry) |

≤ 600 °C |

Material (Inner liner) |

AISI 316L-EN 1.4404 |

Material (Insulation) |

Mineral fibre |

Material (Outer case) |

Material No.: 1.4301 |

Thermal resistance by insulation thickness |

0,37 - 0,56 m²K/W |

| General product features | |

Operating |

Dry, Negative pressure (N), Positive pressure (P-H) |

Room sealed |

No |

Area of application |

Heating systems, Generators, Emergency generators |

Occupation |

Single, Multi |

Suitable for passive house |

No |

Heating technology |

High pressure 5000 Pa, Condensing boiler technology, Low temperature technology |

0036 CPR 9195 027 Rev 03 - ICS 5000 - System chimney.pdf

PDF (1.02 MB)

0036 CPR 9195 036 - ICS 5000 50 - Connecting flue pipe.pdf

PDF (97.96 KB)

0036 CPR 9195 038 - ICS 5000 25 - Connecting flue pipe.pdf

PDF (97.34 KB)

GB-033-DOP-23-07-14 - ICS 5000 25 connecting flue pipe.pdf

PDF (83.61 KB)

GB-036-DOP-22-07-14 - ICS 5000 50 connecting flue pipe.pdf

PDF (83.48 KB)

0036 CPR 9195 027 Rev 05 - ICS 5000 - System chimney 2024-10-28.pdf

PDF (349.53 KB)

0036 CPR 9195 038 Rev 03 - ICS 5000 - Connecting flue pipe 2024-10-28.pdf

PDF (442.91 KB)

027-DOP-2024-10-28 ICS 5000 System chimney.docx

DOCX (42.83 KB)

038-DOP-2024-10-28 ICS 5000 Connecting flue pipe.docx

DOCX (43.6 KB)

GB-033-DOP-23-07-14 - ICS 5000 25 connecting flue pipe.pdf

PDF (83.61 KB)

GB-036-DOP-22-07-14 - ICS 5000 50 connecting flue pipe.pdf

PDF (83.48 KB)

0036 CPR 9195 027 Rev 05 - ICS 5000 - System chimney 2024-10-28.pdf

PDF (349.53 KB)

0036 CPR 9195 038 Rev 03 - ICS 5000 - Connecting flue pipe 2024-10-28.pdf

PDF (442.91 KB)

027-DOP-2024-10-28 ICS 5000 System chimney.docx

DOCX (42.83 KB)

038-DOP-2024-10-28 ICS 5000 Connecting flue pipe.docx

DOCX (43.6 KB)

Helpful sections for chimney installers

A set of training courses at our centre in Washington, Tyne & Wear.

We're available to discuss the technical aspects of our product range.

Helpful sections for chimney installers

3D modelling object available for download.

We're available to discuss the technical aspects of our product range.

Helpful sections for chimney installers

Products available to purchase, as well as full information on our range.

Apps designed for seeing how our stoves and outdoor appliance look like in your homes and gardens, using the latest technology. We also have our excellent stove and chimney installation app, which has all the technical information and guides for installing our systems.

This App allows the user to see what a wood burning stove looks like in a room, as well as calculating the components required.

Simply point and see – it’s as simple as that with our new AR Outdoor Fireplace Designer.

This app was designed for installers to have all the information they require in a few quick clicks.