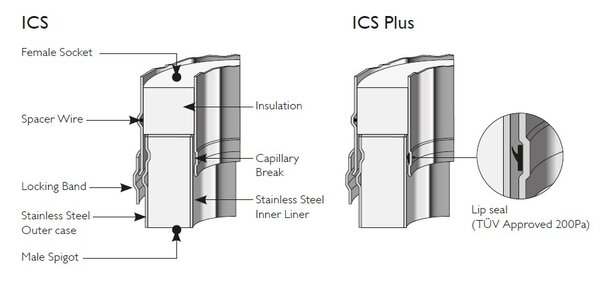

ICS is CE Certified to EN1856-1 TÜV 0036 CPR 9195 001 with designations: ICS is CE Certified to EN1856-2 TÜV 0036 CPR 9195 041 with designations:

VENTILATION

It is very important that sufficient air for combustion and ventilation is provided to the room containing the appliance, to enable correct and efficient working of the appliance and chimney system. Reference should be made to the appliance manufacturer’s instructions and recommendations are also given in the Building Regulations Document J, CIBSE guidance notes and BS 5440.

CARBON MONOXIDE ALARMS

The carbon monoxide alarms should comply with BS EN 50291

Where a new or replacement fixed solid fuel appliance is installed in a dwelling, a carbon monoxide alarm must be provided in the room where the appliance is located.

Please follow manufacturer’s instructions with regards to siting and fixing or alternatively :-

N.B Provision of a carbon monoxide alarm should not be regarded as a substitute for correct installation and regular servicing.

PAINTING

If painting of any external sections is required, it is important to de-grease, dry and prime the exterior surface prior to the application of appropriate heat resistant paint. Schiedel Chimney Systems can provide to special order, chimney sections and accessories painted to an extensive range of British Standard RAL colours – details on application.

Please note that conditions in coastal areas means that corrosion is more likely to occur. Please contact us for advice on any such installation.

HANDLING

It is advised that suitable PPE should be used when handling the products.

DELIVERY TO SITE AND STORAGE

Components should be carefully transported and off loaded. They should be inspected to ensure they have not been damaged, and should be stored off the ground and under cover so that they are protected from accidental damage and the adverse effects of weather.

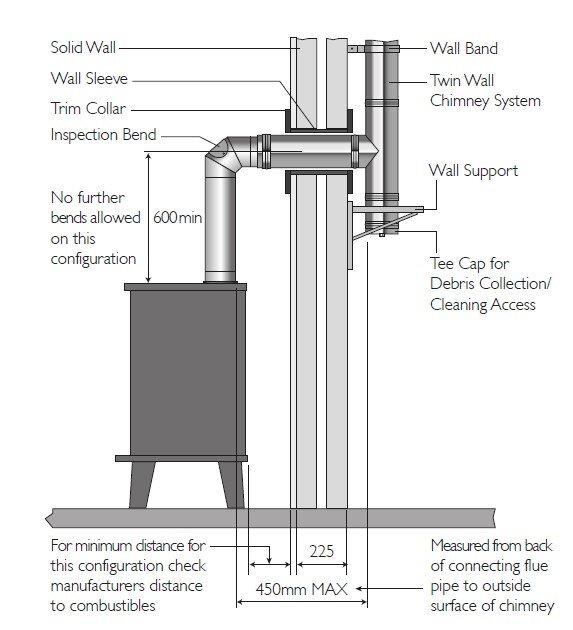

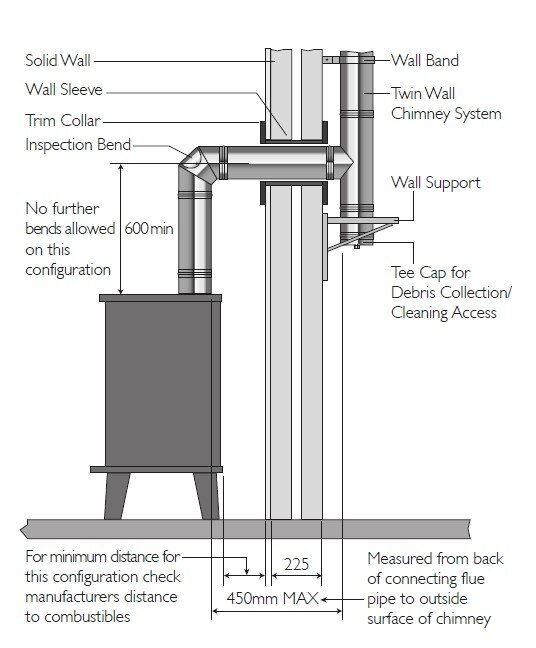

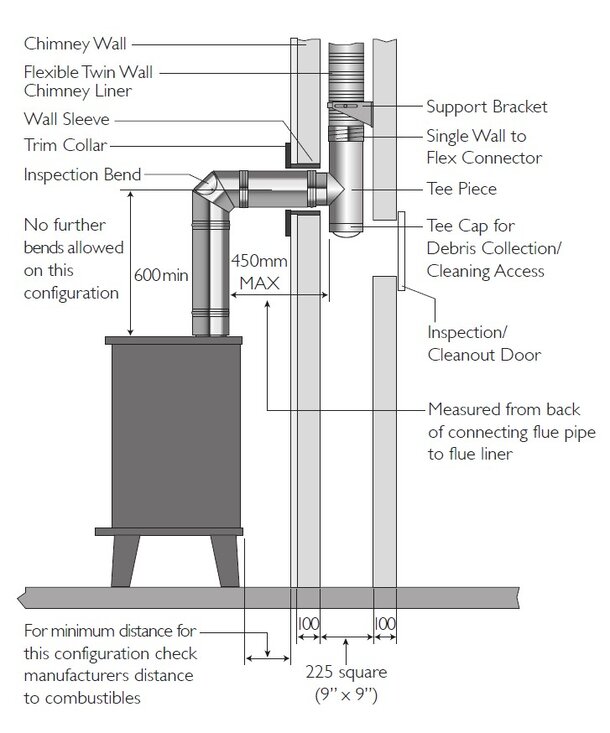

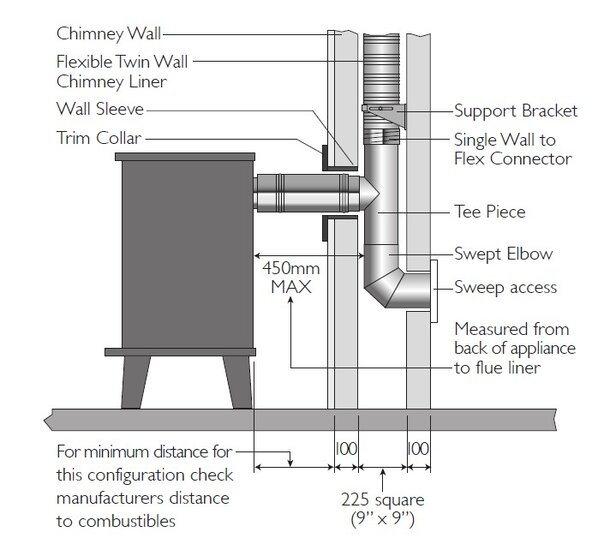

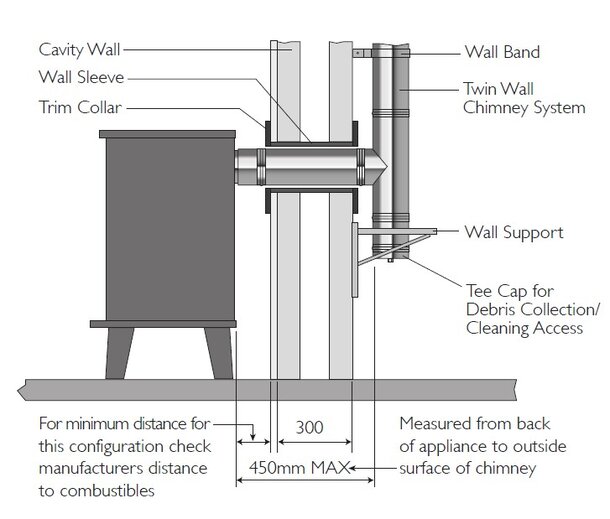

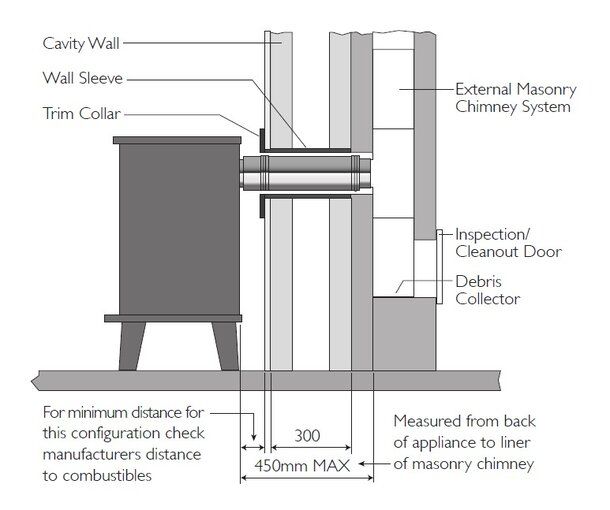

Connecting Flue Pipe

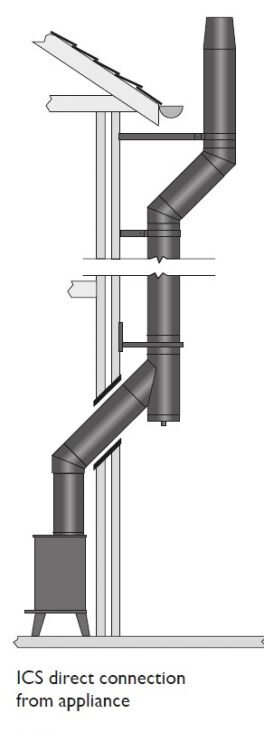

APPLIANCE/CHIMNEY CONNECTION

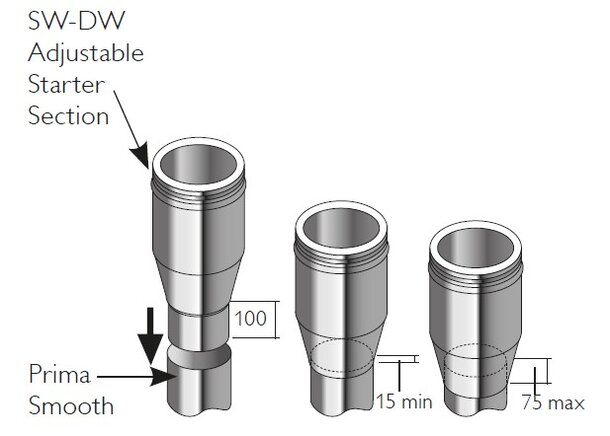

Connection to the appliance can be made using Prima Smooth, Prima Plus or alternative approved single wall connecting flue pipes, or ICS.

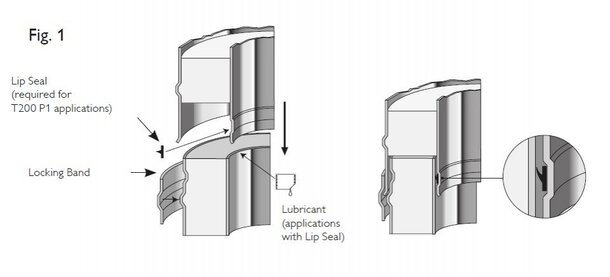

This must be done by using the appropriate appliance connector. When a single wall connecting flue pipe is used to connect an appliance to the chimney, the lower end of the chimney section must extend a minimum of 425mm below the ceiling. When connecting the appliance to the flue pipe all joints between the flue pipes/appliance outlet must be securely caulked and sealed with non asbestos rope (or suitable alternative) and fire cement on solid fuel appliances and using the appropriate lip seal gasket in the case of condensing appliances.

Any flue pipe connection to the chimney MUST be made in the same room as the appliance.

CONNECTION TO DRAUGHT DIVERTER

Where the appliance features a draught diverter the connection should rise vertically from it for at least 600mm before any change of direction (unless otherwise specified by the appliance manufacturer). This is in accordance with the recommendations contained in BS 5440 Part 1 section 4.1.5.

CONNECTING FLUE PIPE DIAMETER

The chimney size should be as recommended by the appliance manufacturer. Where there is a requirement for a flue diameter smaller than the appliance spigot, then the operational requirements of the appliance and the configuration of the flue must satisfy the flue sizing requirements of EN13384-1 for single appliances, and EN13384-2 for multi appliances.

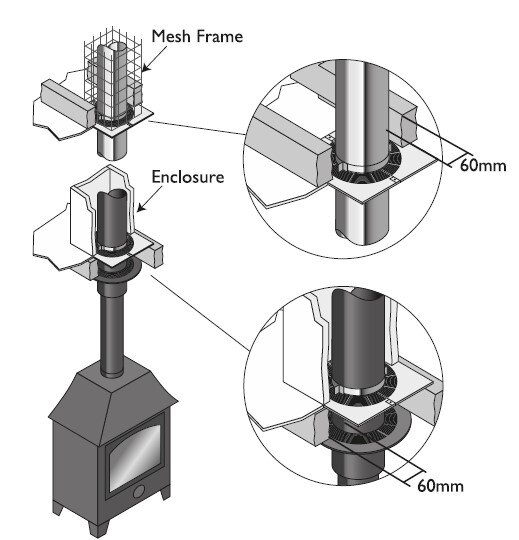

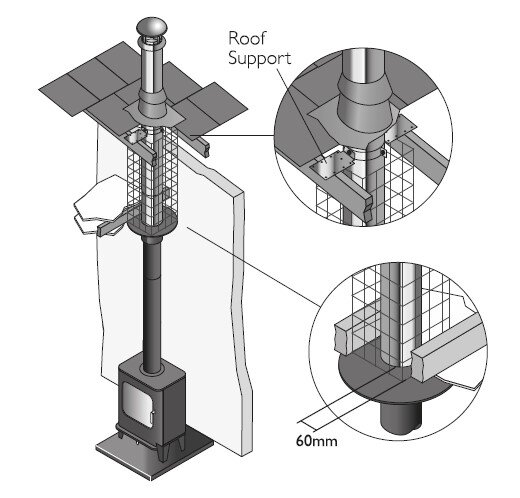

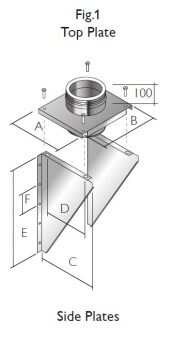

DISTANCE TO COMBUSTIBLES

In accordance with building regulations, it is essential that the correct distance to combustible material is maintained on connecting flue pipes. On solid fuel applications, where there is a risk of soot fire, on unmeasured (NM) designated single wall product, this distance is 3 x ØInt of the pipe, e.g. for Ø130mm the distance is 390mm and for Ø150mm the distance is 450mm to combustibles on both painted and non painted variants. On measured (M) single wall or double wall products this distance will be as declared by the chimney manufacturer. On ICS25, when used as a connecting flue pipe, this distance has been measured and is set at 100mm.

ENGLAND / WALES

The installation must be carried out by a HETAS, OFTEC, NAPIT or APHC registered installer for England and Wales.

SCOTLAND

All installations need to be carry out by a competent person this could be a HETAS, OFTEC, NAPIT or APHC registered installer or have been approved by the local building control authority.

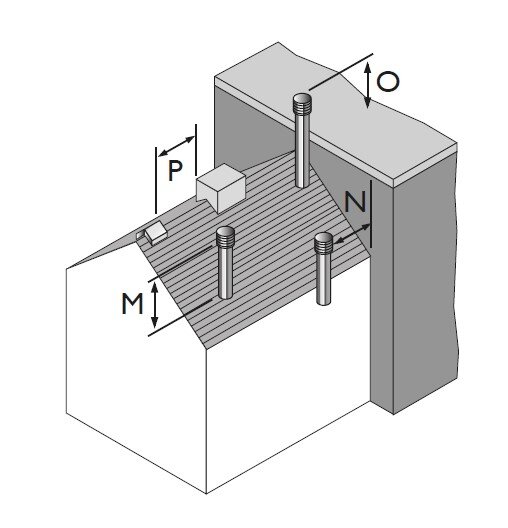

M

N

O

P

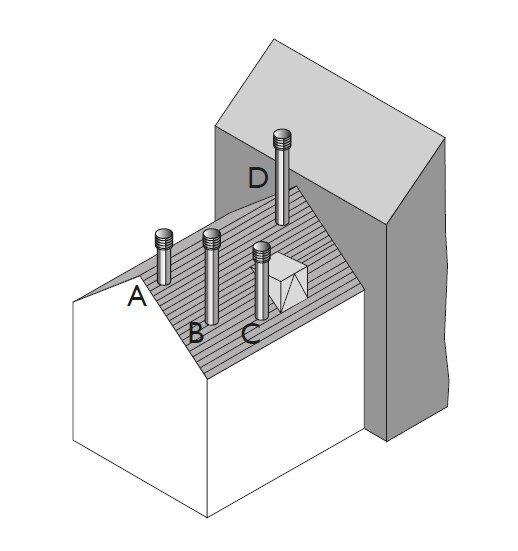

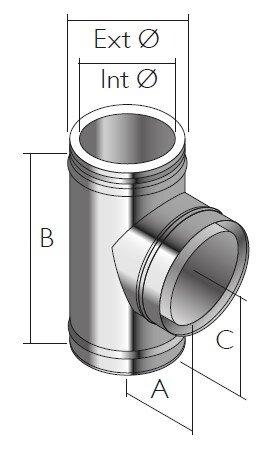

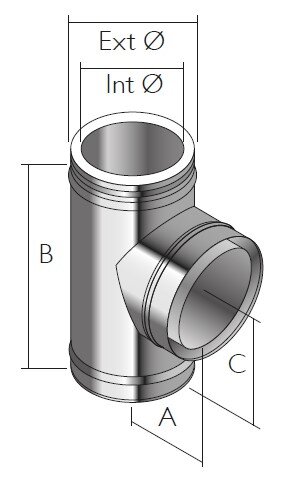

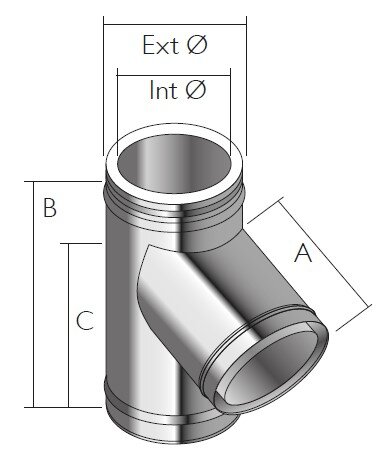

A

B

C

D