(Washington, Tyne and Wear, 07. December 2022) As a business, Schiedel cares about the environment and continuously looks for ways to reduce our carbon footprint. We know that the times and our planet are changing, and we need to adapt to ensure that we plan for a greener, more sustainable future as a business.

News

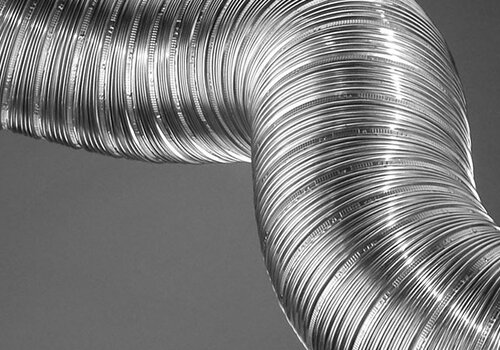

The 585-885mm effective ICID Adjustable Length is a new telescopic 2-piece adjustable in the ICID range, adding to the two we already offer....

News

A remarkable installation of a Magnum Firechest with a Pumice Chimney System took place Down Under in the Australian Bush.

News

We have introduced a new product as well as an update to an existing product to make it much more installer friendly. The new is the Adjusta...