Plant Engineering from A to Z

For your demanding industrial projects, we offer far more than just the exhaust gas system itself. We see ourselves as your strategic partner, providing a comprehensive range of services and digital tools designed to make your entire project process efficient, safe and cost-effective. Our goal is to support you throughout the entire lifecycle of your facility - from the initial sketch to maintenance and condition monitoring.

We act as your "one-stop shop" partner, providing personal and results-oriented support through all phases of your project. A key advantage for you: with an in-house production rate of over 90%, we guarantee not only the highest "Made by Schiedel" quality but also flexibility and on-time delivery - even for complex custom-made solutions.

We act as your "one-stop shop" partner, providing personal and results-oriented support through all phases of your project. A key advantage for you: with an in-house production rate of over 90%, we guarantee not only the highest "Made by Schiedel" quality but also flexibility and on-time delivery - even for complex custom-made solutions.

Every industrial project begins with an individual set of requirements. Our experts provide professional support during the system selection process and create tailor-made planning concepts for your exhaust gas systems. We do not just advise you from behind a desk: our specialists conduct expert on-site inspections to precisely assess the local conditions. On this basis, we support you in preparing legally compliant tenders and provide you with precise component drawings.

Every industrial project begins with an individual set of requirements. Our experts provide professional support during the system selection process and create tailor-made planning concepts for your exhaust gas systems. We do not just advise you from behind a desk: our specialists conduct expert on-site inspections to precisely assess the local conditions. On this basis, we support you in preparing legally compliant tenders and provide you with precise component drawings.

The technical safety of your industrial facility is our top priority. Our technical team handles the sizing and creates technical calculations according to current standards. In addition, we precisely calculate chimney heights and necessary offset calculations. We also stand by your side regarding emission and noise control: we perform professional sound measurements and manage the individual design of exhaust gas silencers tailored exactly to your requirements.

The technical safety of your industrial facility is our top priority. Our technical team handles the sizing and creates technical calculations according to current standards. In addition, we precisely calculate chimney heights and necessary offset calculations. We also stand by your side regarding emission and noise control: we perform professional sound measurements and manage the individual design of exhaust gas silencers tailored exactly to your requirements.

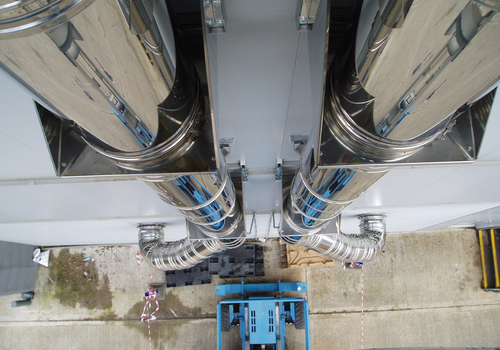

Following the proposal phase, we manage the entire interface coordination as part of our "one-stop shop" principle. We centrally steer all project partners involved, organize logistics - including crane and platform operations - and ensure professional on-site installation.

Schiedel remains by your side even after project completion. Before the initial commissioning, we perform thorough technical leakage tests for quality assurance. With our services for regular maintenance and condition monitoring, we ensure maximum operational safety and the long-term value retention of your industrial facility.

Following the proposal phase, we manage the entire interface coordination as part of our "one-stop shop" principle. We centrally steer all project partners involved, organize logistics - including crane and platform operations - and ensure professional on-site installation.

Schiedel remains by your side even after project completion. Before the initial commissioning, we perform thorough technical leakage tests for quality assurance. With our services for regular maintenance and condition monitoring, we ensure maximum operational safety and the long-term value retention of your industrial facility.

In modern plant engineering, time is a decisive factor. To accelerate your processes and eliminate potential errors in advance, we rely on intelligent digital solutions. Our extensive 3D/ BIM CAD Database enables the seamless integration of our components directly into your digital plant planning. In this way, Building Information Modeling becomes a genuine driver of efficiency.

Benefit from decades of experience in industrial plant engineering. Together, we will find the optimal solution for your next project.

Norway

Non-Residential

Schiedel Norway was selected as a proud supplier for a highly critical phase in the vessel’s life: its significant upgrade and 12-meter extension. This comprehensive rebuild was initiated in close cooperation with the shipyard, Vard, and became necessary after the original construction faced severe technical challenges and stability issues that threatened the full functionality required for its complex research operations. Schiedel was specifically tasked with designing and supplying the complete exhaust system for the vessel's powerful generators. Our mission was not merely to replace components, but to contribute a fundamental solution that would finally allow this world-class research and expedition vessel to meet its stringent performance and structural requirements - and ultimately achieve seaworthiness.

Italy

Non-Residential

The iconic Torre Velasca, a prime example of Brutalist architecture in Italy and Europe, underwent a comprehensive redevelopment from 2020 to its grand reopening in 2025. This massive project revitalized both the facade and interior, alongside a radical overhaul of its plant engineering to integrate state-of-the-art technological systems within its historically significant architectural context. Our contribution to this landmark renovation began in spring 2023 and concluded later that year. Schiedel supplied six ICS and ICS 5000 insulated double-wall chimney systems, ranging from 250 mm to 600 mm in diameter. These were crucial installations, connecting to 670 kW and 900 kW condensing boiler collective systems, fire-fighting motor pumps, generator sets, and kitchen hoods.

Netherlands

Non-Residential

Schiedel supplied a complete exhaust system with sound attenuation for a leading builder of exclusive superyachts. The project required not only advanced engineering and custom components, but also the expert and seamless installation by the Schiedel installation team. This total concept, was crucial to the success of the project, the first of a new series of limited edition superyachts.

United Kingdom

Non-Residential

Supply and installation of 22 stainless steel system chimneys with a supporting mast for the energy centre. The mast and chimneys had to be lowered by crane through an opening in the roof of the building. This meant that the plan needed to come together for the supply and erection of the chimneys on the mast sections, to be delivered to site in full and on time to tie in with the crane hire.

Netherlands

Non-Residential

As part of this project, Schiedel designed custom planning for a major telecom provider in the Netherlands to integrate a new emergency power generator with noise attenuation into a building with limited space. The client, one of the largest telecom and data providers, opted for a more powerful generator. Schiedel solved the dual challenge of lack of space and strict noise standards with smart engineering and acoustic measures.

Netherlands

Non-Residential

Schiedel implemented a range of flue gas, baking vapor, and cooling air ducts for an international producer of exclusive pasta and bakery products. This project was essential to the success of a new production line, where high standards for food safety and operational efficiency were paramount. Sustainability was equally central to the mission. The work was completed exactly as intended.

United Kingdom

Non-Residential

Supply and installation of 3 x Ø250 system chimneys designed to serve Viessmann Vitoplex 200 condensing boilers, along with 1 x Ø350 system chimney catering to a Viessmann Kob Pyrot biomass boiler. The chimneys are configured to run horizontally from the plant room, transitioning seamlessly into an aluminum-clad windshield that rises vertically through the curved roof of the Energy Centre plant room, ensuring efficiency and durability.

United Kingdom

Non-Residential

To ensure uninterrupted backup power for Gartnavel General Hospital, the project involved the delivery and installation of four 450 mm diameter chimneys. These chimneys supply the generators and were connected to the containerized engine rooms via a tailor-made frame construction. This clever design allowed the horizontal pipes to be stacked in proper, parallel pairs. This precise arrangement was maintained right up to the main building. From there, the chimneys continued horizontally before making a decisive vertical curve to finally reach an impressive height of 40 meters.

United Kingdom

Non-Residential

Supply and Installation of 6 x Ø500 System Chimneys serving FG Wilson Gen Sets providing back up power to the Hospital. The exhausts needed to run horizontally above the entrance to the hotel before rising vertically to reach the roof of the energy centre, from where a further extended horizontal run was required with support before turning into th e main vertical runs supported from the existing concrete stack.

United Kingdom

Non-Residential

We supplied and installed five ICS 5000 Ø350 system chimneys to serve the backup generator sets at the Research Centre. A key challenge was to minimize their visual impact on the building's aesthetics. To achieve this, the framework and outer casing of the chimneys were soda blasted, a process that allowed them to blend seamlessly with the surrounding structure, ensuring both functionality and visual harmony with the existing architecture.

Italy

Non-Residential

The facility features comprehensive industrial processes that encompass every stage of food production: from dough preparation and filling creation to cooking, drying, cooling, and finally, storage, packaging, and preservation. Our mandate involved the delivery and installation of flue gas exhaust systems dedicated to two large-capacity steam generators essential to the food processing line.

Netherlands

Non-Residential

At a facility for an industrial candle wax producer, Schiedel successfully designed and installed a high-performance exhaust system for a new boiler. Executed in close coordination with the boiler manufacturer, this project was vital to ensuring the safety and constant availability of essential process heat. Given the high stakes for the plant’s operations, the implementation demanded an exceptional level of technical precision and attention to detail.

Serbia

Non-Residential

The project involved the supply and technical support for the installation of 5 ICS 50 Ø1200 system chimneys, each serving a 21MW gas boiler. The chimneys were installed along an 11-meter horizontal route, with a vertical section extending 31.5 meters. The ICS 50 system, known for its ease of installation and thermal insulation, includes Expl/Impl valves and high-temperature-resistant mineral wool insulation for optimal performance.

France

Non-Residential

This project involved the construction and installation of three freestanding chimneys, each around 14 meters high and with a large cross-section. These were supplied and installed by a specialist partner to supply three generators in a large data center in the Hauts-de-France region. The chimneys connected to the units were manufactured using our ICS 5000 system with a cross-section of 400 mm.

France

Non-Residential

The project involved the construction of a new public school building located in Morbihan, Brittany, designed according to the latest dictates of energy-efficient construction and plant engineering and intended to accommodate more than 800 students. The new facility, with a modern and bright design, boasts the presence of more than 500 square meters of solar panels on the roofs, a perfectly insulated building envelope, and an efficient heating system through a mixed gas and biomass combustion power plant.

Italy

Non-Residential

The installation was to take place at a well-known industrial site in the Bologna area, specializing in the constructionand luxury outfitting of motor vehicles, motorhomes, caravans, as well as boats and yachts in the marine & offshore sector. The project involved the replacement of an old, dated and deteriorated self-supporting chimney with a new modular double-wall insulated stainless steel chimney system, slaved to a large capacity boiler for the production of hot water used in the plant's production processes.

Italy

Non-Residential

Located in a prime central Milan neighborhood, this project delivered a new executive and office headquarters for one of Italy's foremost telecommunications leaders. The client, a pioneer in fiber optic technology, maintains a telephony and data network that spans the entire nation. The new headquarters was designed to integrate a comprehensive suite of advanced technological systems. These included state-of-the-art heating, ventilation, and air conditioning, robust emergency power generation, and sophisticated fire suppression systems to ensure maximum operational safety and efficiency.

Germany

Non-Residential

The client was a large hospital in Hamburg, which comprehensively expanded its emergency power supply for the operating rooms to ensure that life-saving operations can continue without interruption even in the event of a power failure. As part of this project, Schiedel supplied the appropriate chimney systems and sound insulation concept for the new diesel-powered emergency generators.