Schiedel Swift Air provides all the benefits of the Schiedel Swift but in addition, neatly and simply delivers combustion air to the heating appliance. Ideally suited to energy efficient buildings, the Schiedel Air System provides an alternative to underground ducting, eliminating the risk of ‘wind’ effect’ influences on the draft of the chimney.

Suitable for timber frame, steel frame and masonry

Suitable for all fuels: gas, oil, solid fuels and biomass.

New build homes

Renovation projects

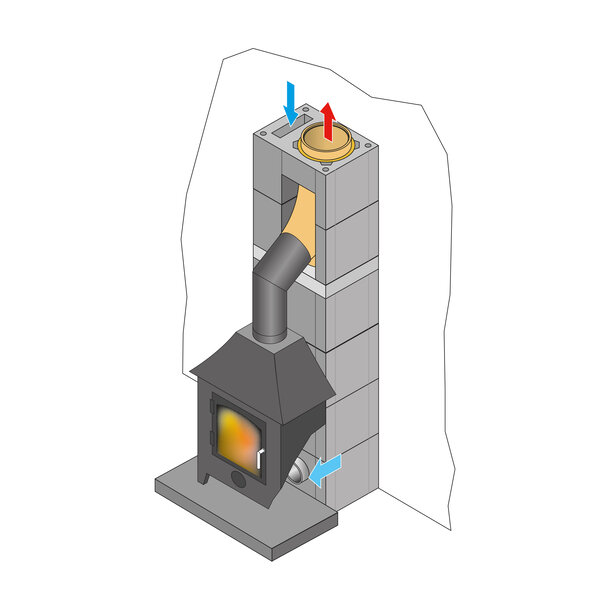

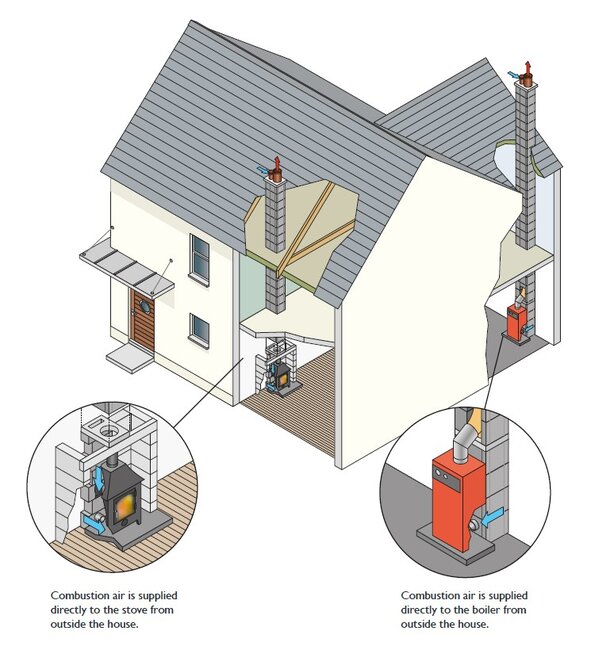

In an A rated house the combustion air required for wood burning appliance like a stove burning logs or wood pellets must be supplied directly to the stove from outside the house.These appliances are called room sealed as they are manufactured not to take air from the room.The Schiedel Swift Air provides all the benefits of the Schiedel Swift and in addition neatly and simply delivers the external air to the stove.

The alternative to Schiedel Swift Air is low level or under floor ducting ideally with air supplies from opposite sides of the house.

The Schiedel Swift Air solution avoids this by ducting the air through an external air shaft in the chimney.

Available in 150mm, 180mm and 200mm internal flue diameters. The size of the chimney block is the same for each flue diameter – 500mm x 360mm x 330mm high.

The heated air circulates within the house. The stove and the boiler do not take air from inside the house so no warm air is lost through the chimneys.