G50 is a key designation of our ICID twin wall system, which is ideal for traditional stoves as well as more innovative appliances, such as pellet stoves, biomass stoves and boilers, mini/micro CHP and even condensing boilers.

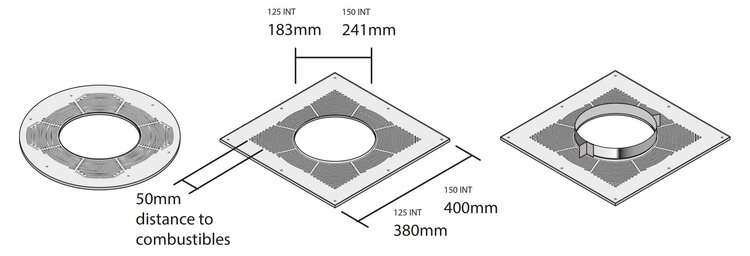

ICID Plus has been tested and approved to meet the latest BS EN1856-1 requirements when passing through either combustible or non combustible floors with a distance to combustible material of 50mm within both the floor cavity and within a shaft. The firestop plates also have a 30 minute fire rating to BS476 Part 20 in line with Approved Document B which covers fire safety.

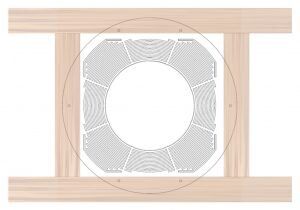

All the tests have been carried out using the latest design of ventilated firestop plate, in both round and square versions and the new ventilated support plate. The updated G50 Ventilated Square and Round Firestop plates have been engineered to provide an increased air flow around the flue, which keeps the area around the chimney inside the enclosure cooler during operation.

There is no requirement to line the timbers to achieve the 50mm distance to combustibles.

ICID’s outer case is load bearing whilst the inner liner is free to expand independently, which allows thermal expansion within each joint. It’s also designed to be particularly resistant to corrosion with a laser welded 316L stainless steel inner liner and case.

Lifetime guarantee.

At Schiedel, we pride ourselves on developing the very best in innovative, long-lasting flueing and chimney solutions.

The ICID system has been manufactured at our Plant in Washington, Tyne and Wear for more than 50 years, giving us the experience to be able to commit to our Lifetime Guarantee and providing peace of mind to our distributors, installers and end users. Our Guarantee is linked to the property in which the product is installed, not to the householder, therefore the guarantee is a transferable asset when the property is sold, providing that the products have been specified, installed and maintained correctly.

Our ICID product range is available in a variety of sizes and finishes, and with our attention to detail on aesthetic design of components, it offers a very attractive option for a wide variety of installations.

The availability of high-quality accessories which are fully compatible with the system and carry the same guarantee, means the installer and the end user can be confident in the compatibility and quality of the complete installation.

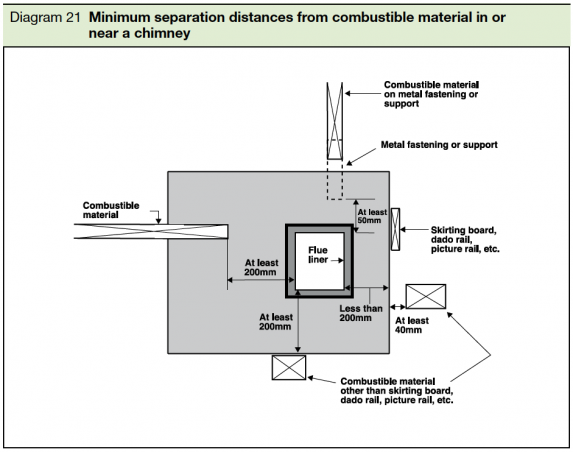

Because the insulation isn’t natural, like pumice. This means when burning solid fuel such as wood in a steel chimney, you need 60mm between the steel pipe and the building frame or floor, etc. There’s no need to line the floor area with plasterboard, but a ventilated fire stop plate and support plate must be used.

For Gas and Oil, a distance of 50mm can be maintained and a ventilated fire stop plate and support plate must be used. This is because the temperature is less than it would be for solid fuel.

If it’s non-combustible wall, i.e. won’t burn when heated up, such as a plain, un-rendered brick wall, then 50mm may be used. Remember, brickwork does heat up, but might not spurt into flames, however, a wooden beam next to it would be heated by the bricks and probably start burning. So this must be taken into account.